3D food printing technology is bringing 3-dimensional digital designs into real-world objects which are edible. Nowadays 3D food printers are being used in many high-class restaurants and homes and started becoming an essential part of technologies that can change the way we cook or produce food.

With the help of 3D food printing, production can be easily and perfectly controlled based on customer demand. It plays an increasingly important role in food processing as a complementing technology. In these food preparation methods, the quality of 3D printed food items depends on the process and planning rather than traditional food people’s skills. Thus, the bulk food product producers are focusing on the application of 3D food printing and to disrupt the consumer demand from the food industry.

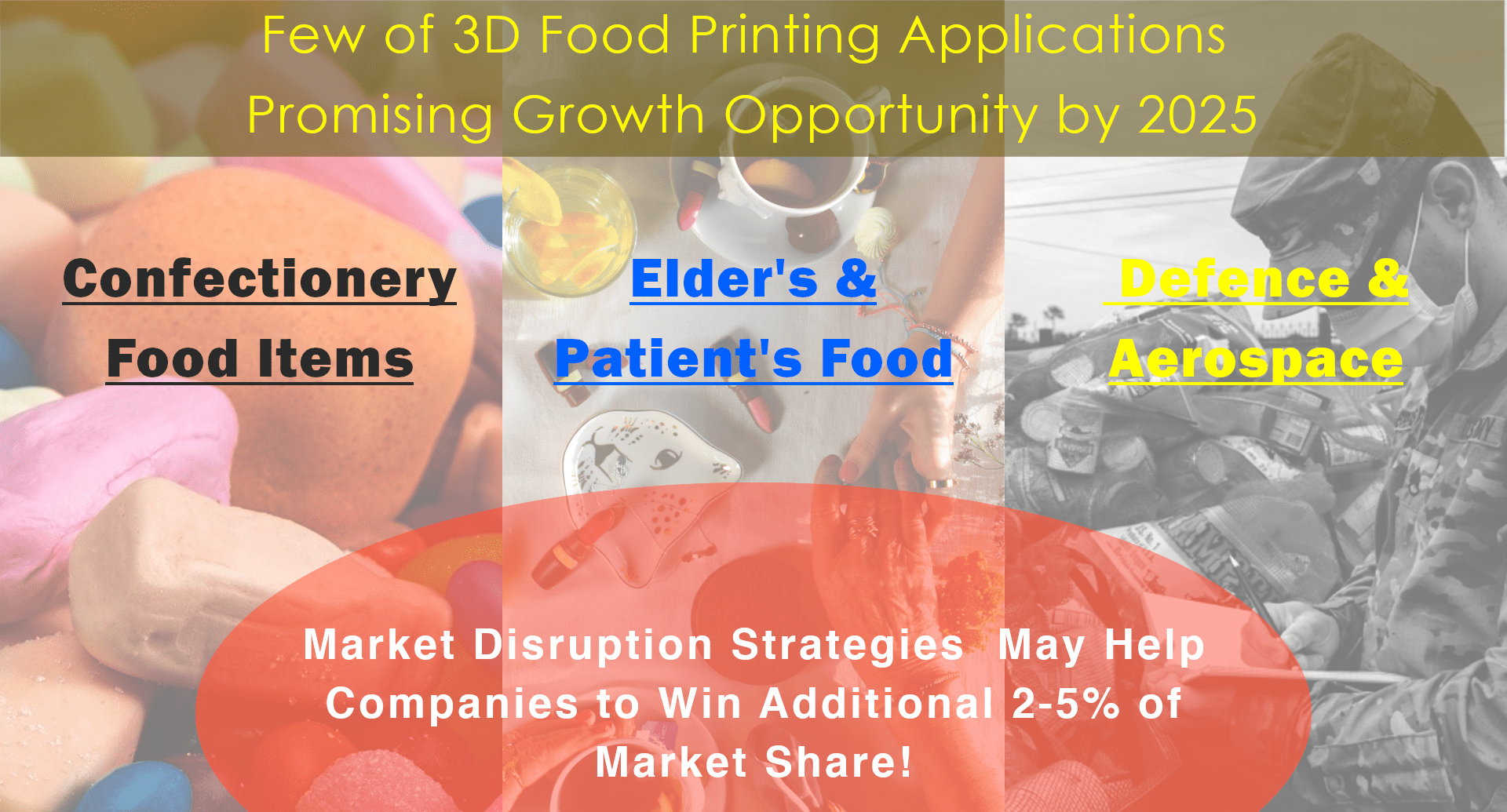

Trending Applications of 3D Food Printing Technology

The biggest application of 3D food printing is in the manufacturing the customized food. The fact that it is due to 3D printing technology food has become highly customizable according to consumer preferences thereby also allowing for hyper-customization. Thus, it is allowing food item producers/ users to print food by its taste favorites, health needs which is right for them.

1) Increased Adoption of 3D Printing Technology in the Chocolate and Confectionery Industry

Use of 3D food printing in the chocolate industry is providing customers with more options for their customizable treats. Owing to advantage chocolate and confectionery supplier have now improvised their production lines. In February 2020, Barry Callebaut’s, Swiss chocolatier, who supplies chocolates to its client such as Hershey and Nestlé, has successfully developed 3D printed chocolate at larger scale. This came after Barry Callebaut consumer research concluded that 70% of the consumers are agreeing to try innovative chocolate products, and 60% want them for sharing it on social mediums. In addition, companies like Hershey, Nestlé, Mars, and Mondelez International has been already experimenting with 3D printed chocolate for the last few years. For instance, Hershey scientists are working on 3D printing of designing candy. Whereas, Oreo is using this technology to produce customized crème patterns and flavored cookies.

These all factors indicate, while still in its very early days, 3D food printing has massive potential to revolutionize the food industry. Moreover, this technology can also provide essential, vegan, and gluten-free chocolate to customers. As a result of growing health awareness, this advantage can play vital role in terms of promoting product lines. This 3D chocolate and confectionery food printing application will be rising with more than 15% compound annual growth rate (CAGR) till 2025.

2) 3D Printed Food for Elders and Patients

3D food printing technology can be useful in making foods for people with special mealtime needs such as to make softer meals for elders with chewing or digestion problems. Also, medicine can be presented in the shape of tasty food, instead of pills or powder. In Today’s time, this is the most useful concept for the people with the dysphagia condition. According to various studies conducted, 60-70% of home patients struggle to swallow the regular foods. This opportunity was initially utilized by the company named Biozoon GmbH, a German company, under the consortium, PERFORMANCE (personalized food for the nutrition of the elderly consumers), which used 3D printing technology to develop personalized diet for persons suffering from dysphagia or similar conditions. It developed the concept of 3D-printed meals made from pureed and strained food that holds the same texture and look, and provides additional health benefits. While testing this food with the patients, it had been well received by them. As per the results published, 54% found the texture good, and 43% choose PERFORMANCE meals when it comes to chewing and swallowing difficulties. Further, this fooding has been accepted by few of the lower-level local government entities in European countries. For instance, Swedish municipalities plan to start 3D-printing at care homes for the elderly, stimulating residents’ appetites by taking puréed food look like the real thing. Also, in 2018, Isala Hospital of The Netherlands partnered with a food provider to develop 3D printed meals for their aged care patients. Due this increasing adoption, 3D food printing application for elders and patients’ food is expected to grow between 7-10% CAGR till 2025.

3) Food Printing Utilized by Defence & Aerospace Industries

3D food printing has gain major attention from defence industry this technology offers food production with the real-time need based personalized nutrition. In addition, the food can be customized according to field conditions such as altitude levels, heat, moisture and others. Moreover, this will help to reduce the burden of logistics, longer shelf life food, food packaging and storage and other dietary needs. For Instance, US military planned to use 3D food printing for customized nutrient intake for soldiers, and easy meal preparation on the battlefield. This would increase the impact of 3D food printing in defence industry as well.

Further, in the aerospace industry, the increasing possibilities of short- and long-term space travel, 3D food printing needs to make nutritious food design and delightful eating experience for the tourists. That is why there is a lot of research going on for space food design along with the functional and nutritional aspects of food. Thus, utilization of 3D food printing by defence & aerospace industry may grow with ~5% CAGR or low till 2025. However, revolutionary innovative printers and materials, and sudden market disruption with the aggressive sales and marketing may lift up annular growth rates up to 7% per year.

Market Disruption with Eco-Friendly Customization of Mass Food Production Lines

In mass food production, product personalization/ customization is commonly persisting challenge. Food industry is researching on mass customization techniques to meet individual needs on taste, nutrition, and mouth feel. Currently, 3D food printing is serving as potential solution to overcome drawbacks of current food customization techniques such as lower production efficiency and high manufacturing cost. The only remained constraint is users of the 3D food printer need to be creative and skillful for that.

Moreover, feasible and less wasteful methods of food production will be extremely important for next 5-10 years. Due to which researchers are focusing on developing, 3D food printers can become less waste production by using only the required amount of raw materials for food production. In 2018-19, Dutch university students tried a way to make new 3D-printed cuisine starting from the bread, the most leftover or discarded food in Netherlands. However, they were finally able to develop food from other things such as dumped fruits and vegetables. This incident is an encouragement to world for having disrupted perspective on food leftovers or scraps. In addition, this entire process can also helps to reduce the burden of transport and disposing cost of the food leftovers.

Thus, 3D food printing is going to change the pattern of food production as well consumption along with promoting user’s creativity. Yet, companies’ offering the Eco-friendly 3D food printing machines lines which comes with the mass customization feature will making the market disruptions in the developed nations such as USA, U.K. Canada, Germany, Australia and Japan. Thus, floating the right ways to educate the target customer may help companies to achieve additional 2-5% of market shares in 3D food printing market.